NDT Technologies

Enhancing safety, accuracy, and efficiency, this dynamic implementation safeguards and evaluates underwater constructions, setting new standards in NDT for submerged structures.

Common NDT Technologies

applications:

CUT for Spot Thickness gauging

PAUT scanning for Corrosion

mapping:PAUT and ECT for crack detection

In the underwater industry, the increasing need for continuous inservice assets’ health monitoring and failure risk assessment, faces huge challenges in getting the right data, due to the underwater environment, to the new codes and norms and the difficulty and the cost of Non Destructive Testing (NDT) tools deployment.

We have designed and implemented our own powerful and fully automated NDT solutions based on reputed Evident

instrumentation that we integrate and adapt to the underwater applications requirements.

CUT for Spot Thickness gauging:

Ideal for spot measurements and random corrosion monitoring, conventional ultrasonic gaging is integrated to our Y solution.

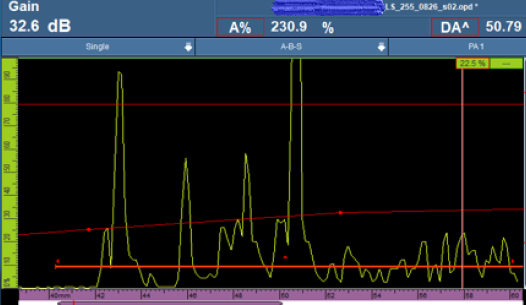

Our solution is based on Evident 38DL PLUS hardware and compatible dual and single element transducers to fit almost every ultrasonic thickness application, ranging from wall thinning measurements of internally corroded pipes with dual element probes to precise thickness gauging of thin or multilayer materials with single element transducers.

Depending on the material to be inspected and the inspection’s specific requirements, a wide thickness range could be covered: 0.08 mm (0.003 in.) to 635 mm (25 in.).

Thickness measurements and High resolution A-scans are displayed in live mode and could be exported automatically to datasets and surveys

PAUT scanning for Corrosion mapping:

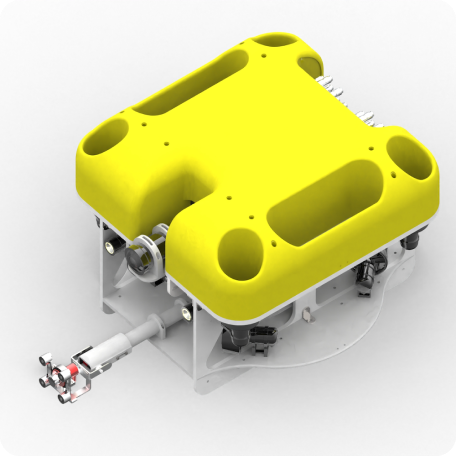

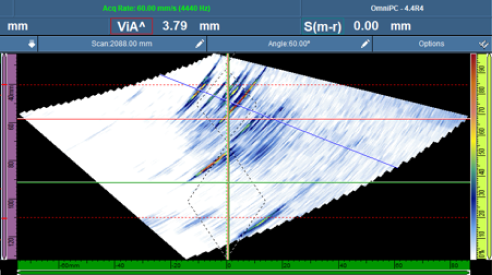

Our X scanner is designed to scan larger surfaces by mapping along two axes (raster scan) using Phased Array Ultrasonic Technique (PAUT) powered by Evident’s PAUT instrumentation. PAUT technique improves corrosion inspection quality, productivity, and efficiency.

Our solution collects high resolution data using FocusPx unit and PA customized probes that meet demanding and challenging inspections with fully encoded Data that can be exported and converted to suit specific and custom clients’ needs.

PAUT and ECT for crack detection:

Girth and long seam welds automated inspection for crack detection is possible thanks to our Z scanner that is designed for angled PAUT or Eddy Current Testing (ECT) techniques using Evident Technology.

While PAUT technique provides weld volume integrity data, ECT performs highly reliable and advanced flaw detection of surface and near-surface defects.

NDT Technologies for Civil inspection industry

Interested in the solution? Send us details for your application and request a demonstration.

we stand unwaveringly by our commitment to provide exceptional support services. Our goal is to empower our clients to achieve their objectives and maximize the value of our products and services.

SUBSCRIBE TO

OUR NEWSLETTER

,

Sign up with your email address to receive news and updates.

Copyright ©2023 Mare custos. All rights reserved.

Privacy policy

Terms of use