CUT for Spot Thickness gauging

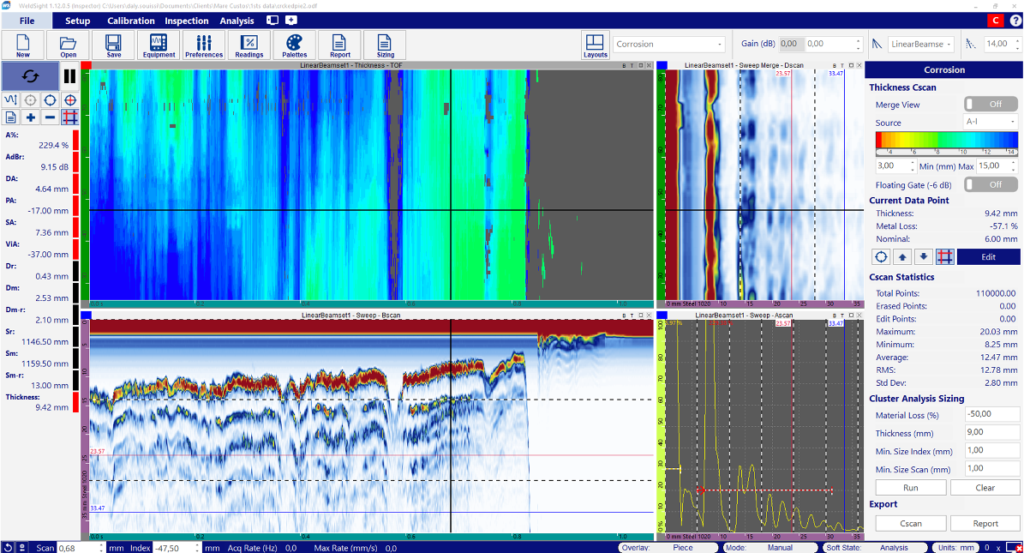

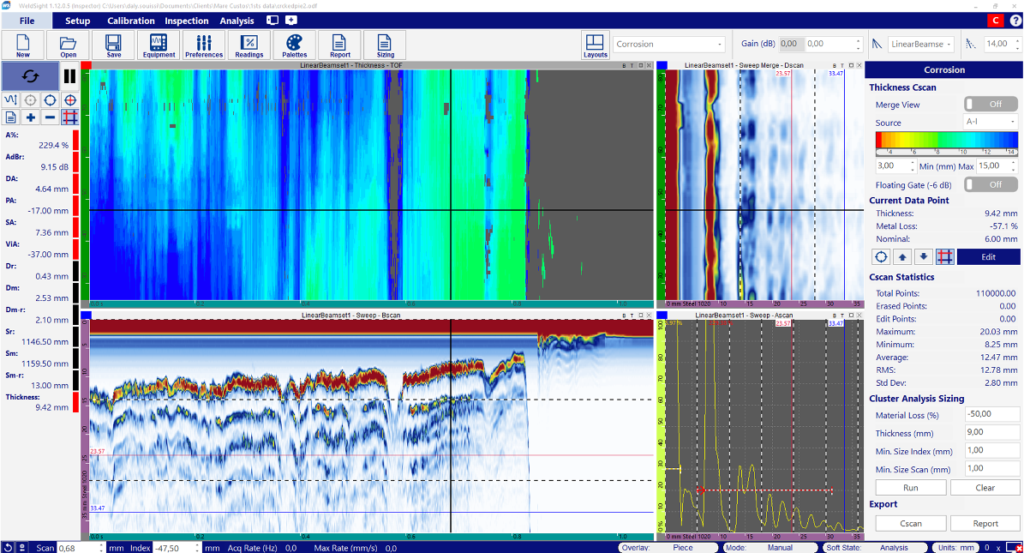

PAUT scanning for Corrosion

mapping:

PAUT and ECT for crack detection

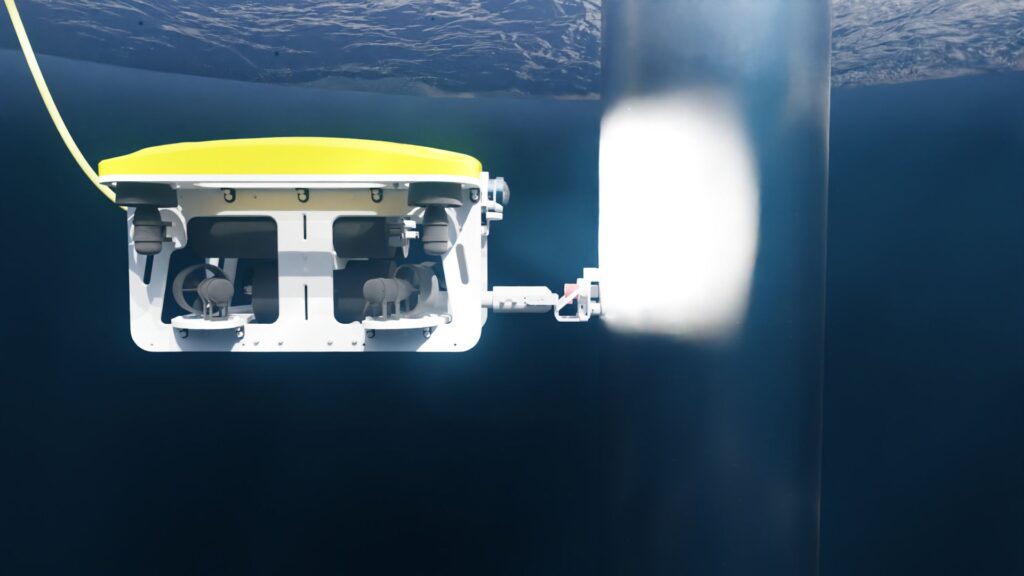

Our X scanner is designed to scan larger surfaces by mapping along two axes (raster scan) using Phased Array Ultrasonic Technique (PAUT) powered by Evident’s PAUT instrumentation. PAUT technique improves corrosion inspection quality, productivity, and efficiency.

Our solution collects high resolution data using FocusPx unit and PA customized probes that meet demanding and challenging inspections with fully encoded Data that can be exported and converted to suit specific and custom clients’ needs.

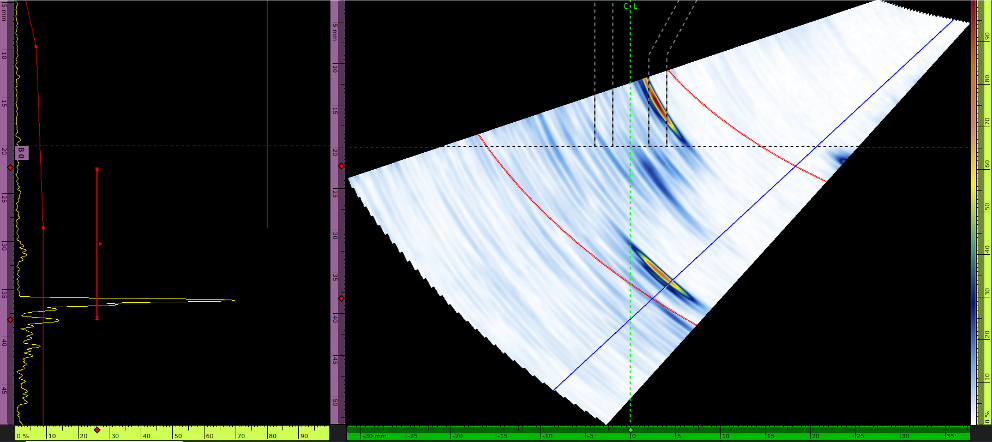

Girth and long seam welds automated inspection for crack detection is possible thanks to our Z scanner that is designed for angled PAUT or Eddy Current Testing (ECT) techniques using Evident Technology.

While PAUT technique provides weld volume integrity data, ECT performs highly reliable and advanced flaw detection of surface and near-surface defects.

Privacy policy

Terms of Service